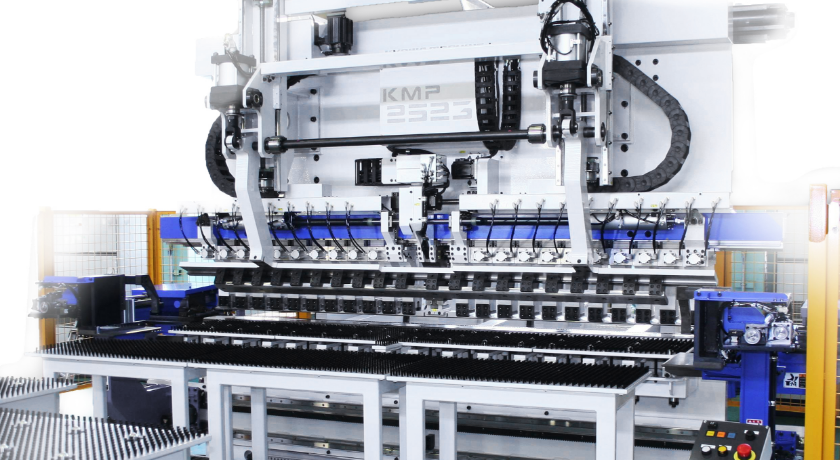

KMP series

Point 01

Shape it your way - complex bends made simple.

High precision. High speed. Easy operation. A flexible panel bender that transforms your production floor.

The KMP Series is a next-generation panel bender that combines all-axis AC servo motor drive with advanced control technology. It delivers precise, high-speed bending of complex shapes - such as radius bends, hemming, and closing - that were difficult or impossible with conventional press brakes. Balancing accuracy, speed, and operability, it dramatically boosts productivity and adapts flexibly to low-volume, high-mix production.

Point 02

Precision. Speed. Efficiency - elevated.

The next generation of bending, with automatic angle detection, correction, and programming.

Equipped with advanced angle detection and automatic misalignment correction, the KMP Series ensures high processing accuracy. It supports a wide range of shapes and helps build a more adaptable production system. With shorter takt times and high-speed operation, it also contributes to greater overall productivity. The machine can automatically generate optimized bending programs by reading CAD drawings in DXF format, significantly streamlining setup tasks. This is a next-generation solution that pairs energy-saving design with powerful performance.

KMP20

Designed for space efficiency, the KMP20 delivers high performance with all-axis AC servo motors - achieving both precision and productivity.

Learn More

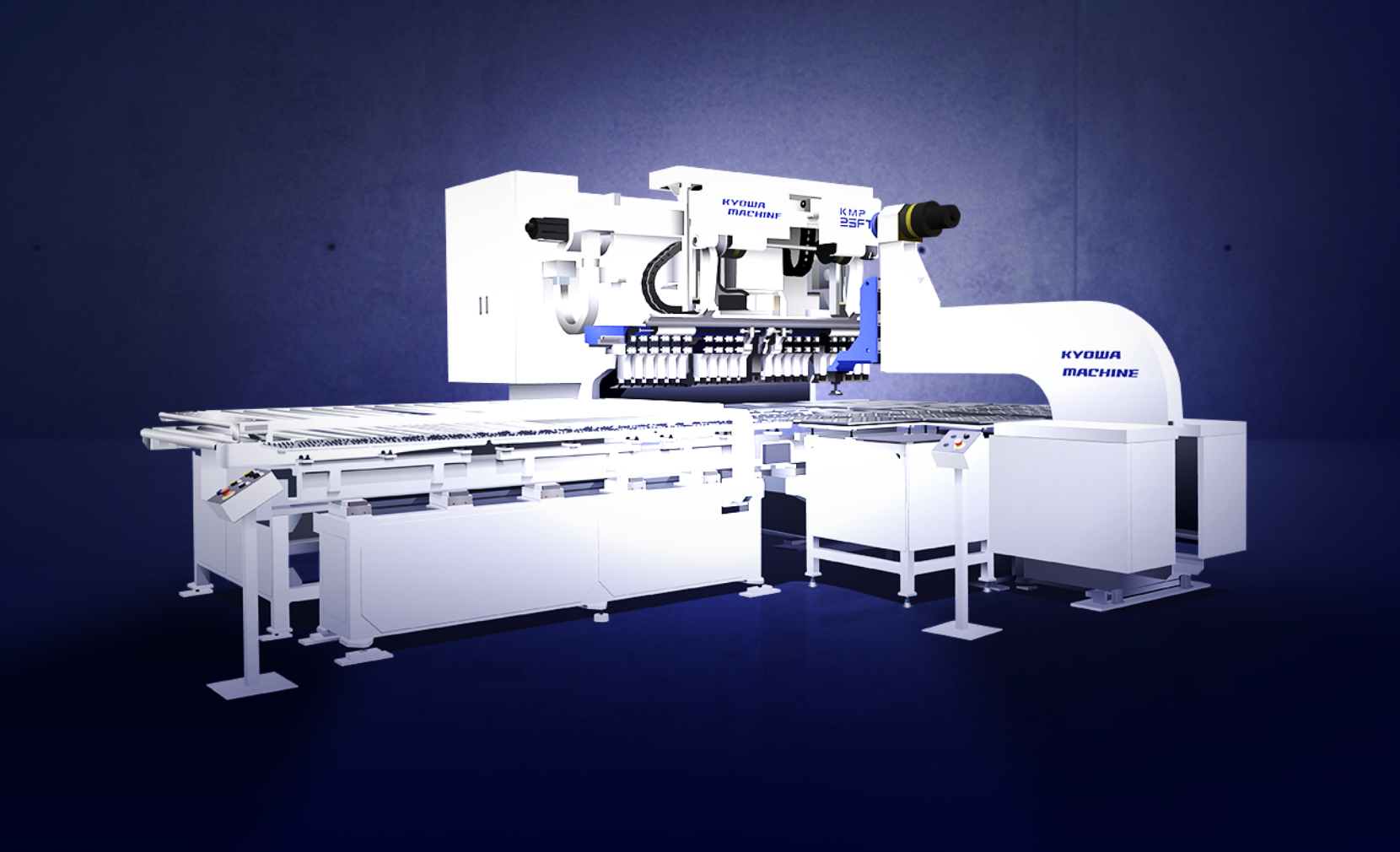

KMP25

Built to handle material thicknesses up to 2.3 mm, the KMP25’s all-axis AC servo system offers outstanding flexibility and greatly expands processing possibilities.

Learn More

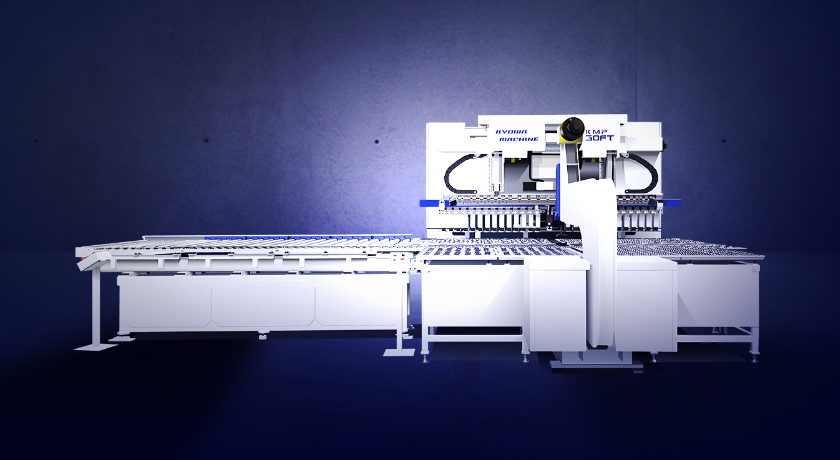

KMP30

Combining exceptional flexibility with precise operability, the KMP30 supports a wide range of applications - including complex shapes that were previously difficult to handle.

Learn More

KMP LINE

Flexible support for production line evolution with various KMP lines that enable labor-saving and unmanned operation.

Learn More

KMP 25FF / 30FF (Semi-Automatic)

KMP 25FF / 30FF — A semi-automatic panel bender with front feeder, combining high productivity and multi-product adaptability.

Learn More

Inline Press Machines and Other Products

High-precision, high-speed inline punching machine for sheet metal processing.

Learn MorePanel Bending

Panel Bending

Panel Bending

Panel Bending

Panel Bending

Panel Bending

Experience unmatched performance and accuracy.

Our panel benders are engineered with cutting-edge technology to reduce takt time and increase processing precision. They handle complex, varied shapes with ease - delivering both superior forming capabilities and efficiency. These advanced bending solutions empower manufacturers to meet diverse customer needs and produce higher-quality products with greater responsiveness. We offer new value for the future of manufacturing.

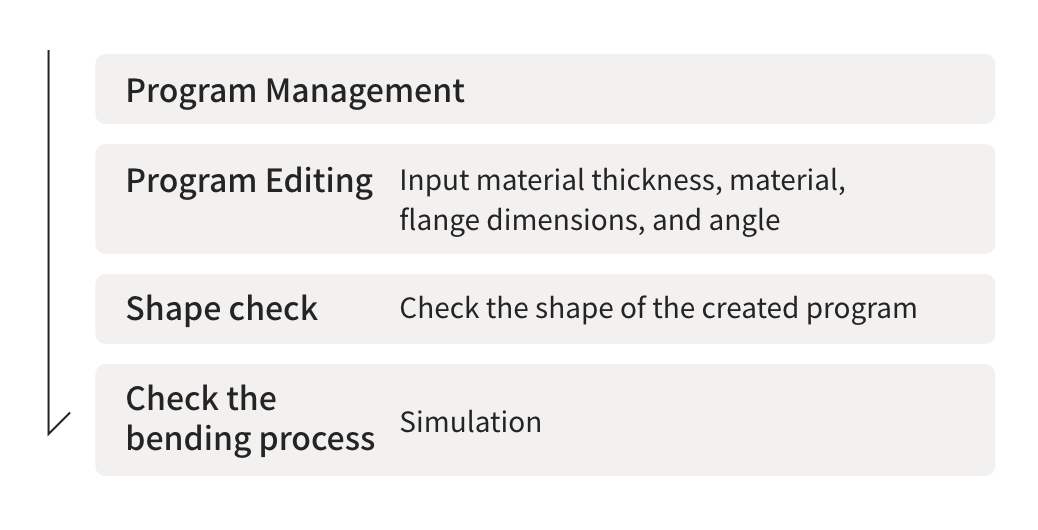

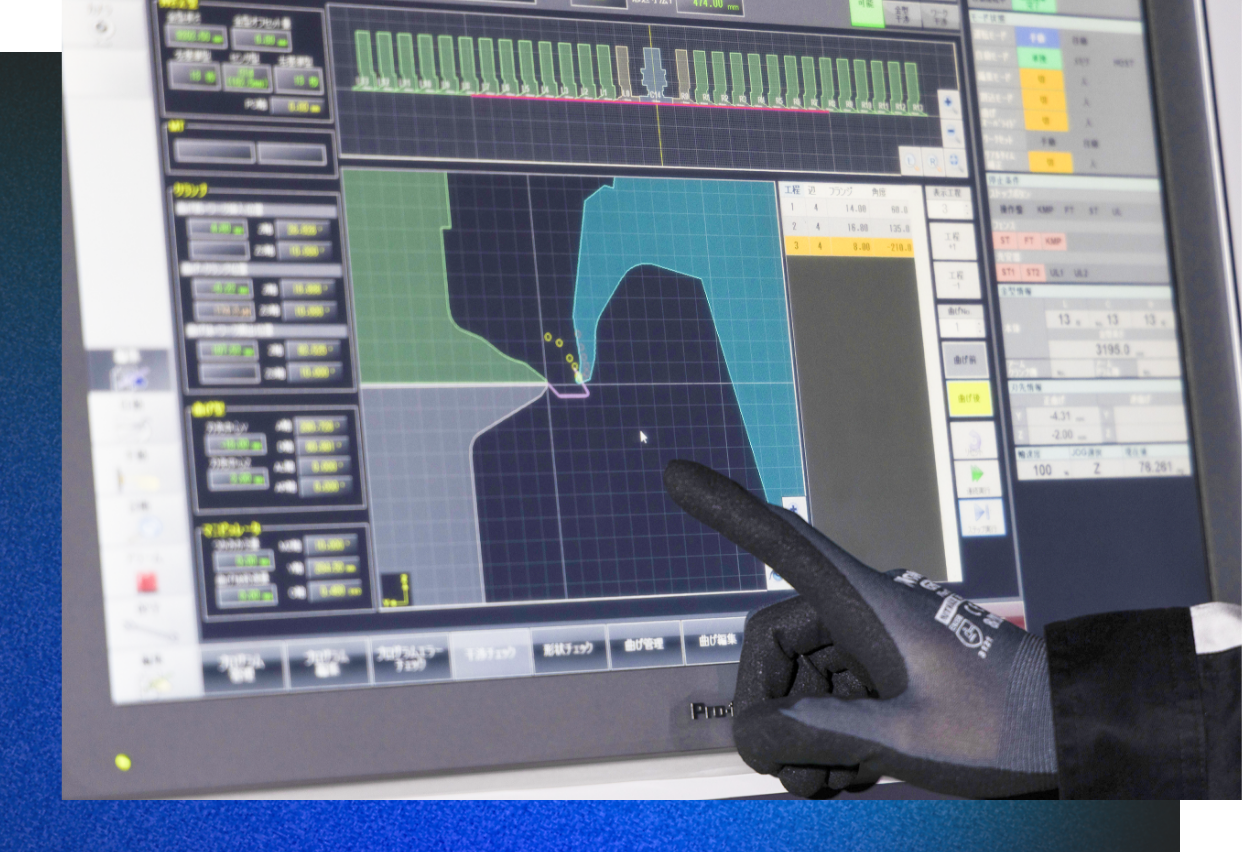

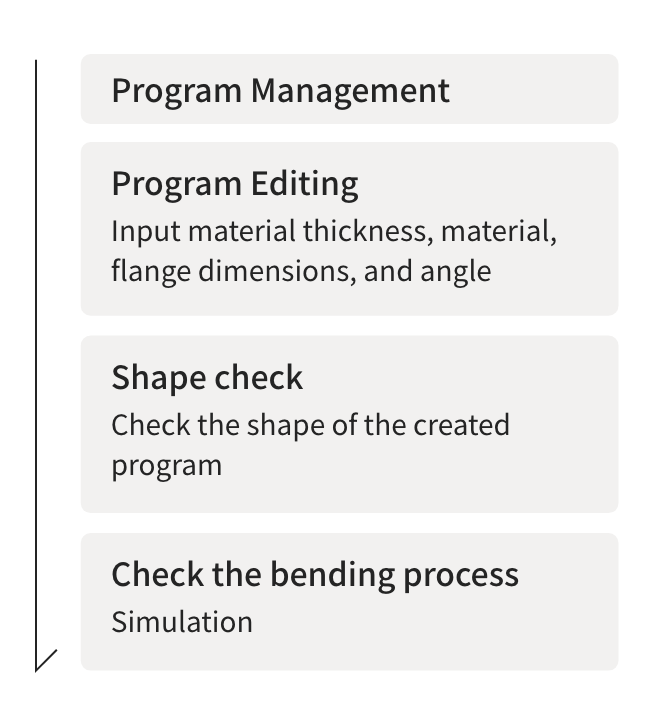

KMP Programming System

In-house developed. Intuitive and efficient.

Simply input values via the touch panel - the machine handles the rest.

Simulate bending operations directly on the control screen.

Built-in IoT system provides centralized control for monitoring, diagnostics, and maintenance.

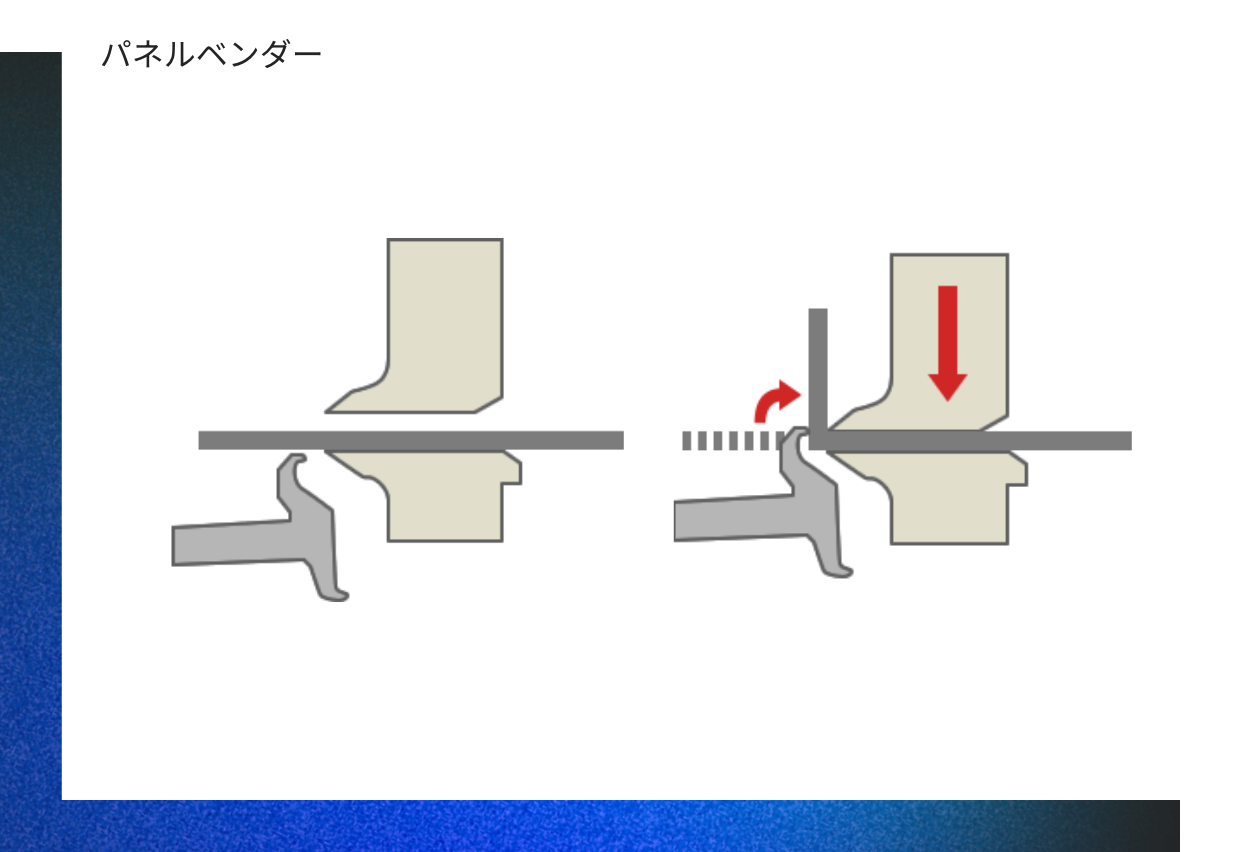

Patented Core Technology

Our patented “Sheet Metal Bending Clamp Device” applies pressure from the upper die to eliminate the “spring back” common in conventional press brakes. This innovation enables greater pressing force while reducing machine size - allowing safe, precise, and versatile bending of complex shapes.

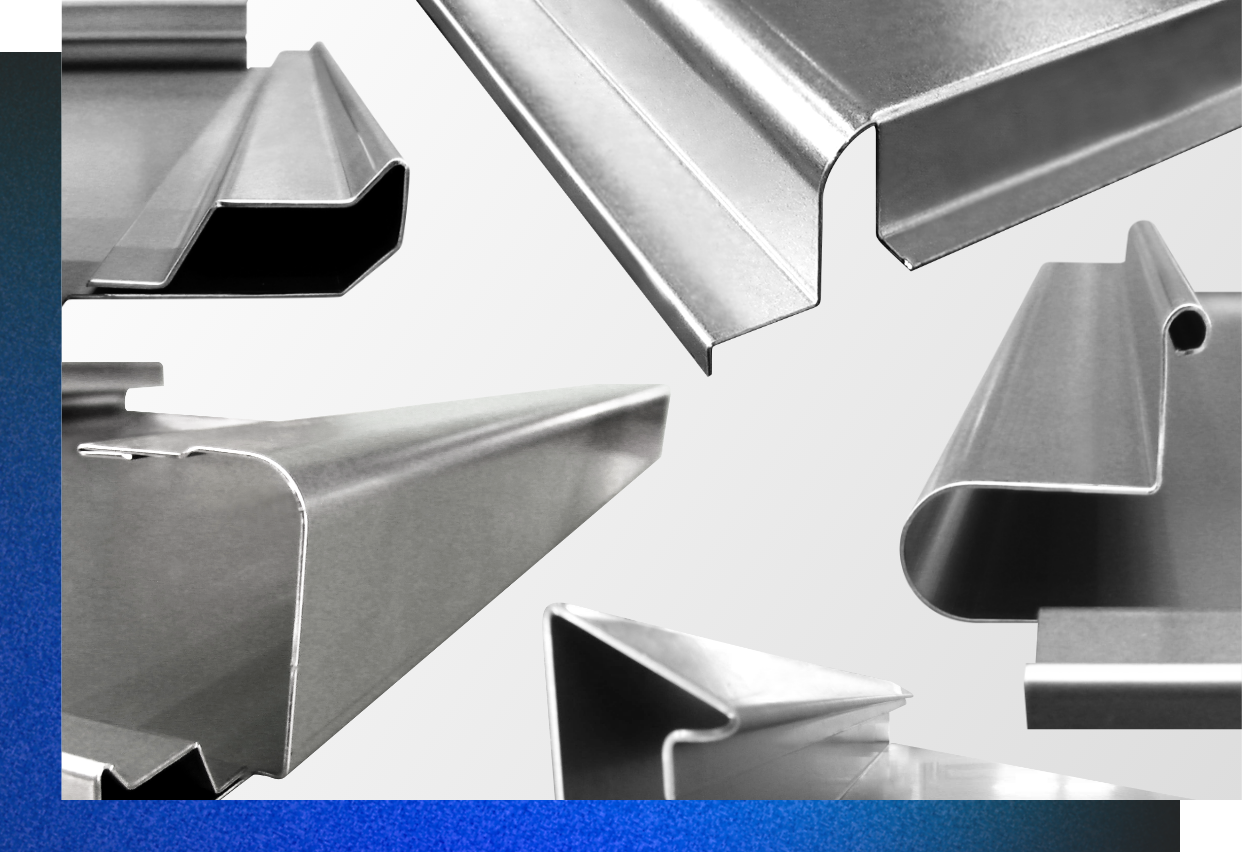

Sample Bend Gallery

The examples shown represent just a portion of what’s possible. We also accommodate custom shapes and specifications. Please feel free to contact us for details.

Our machines serve as vital production equipment across a range of industries.

Commercial

kitchen equipment

Elevators

Lockers

Industrial refrigerators

Office furniture

Doors

Distribution boards

HVAC systems

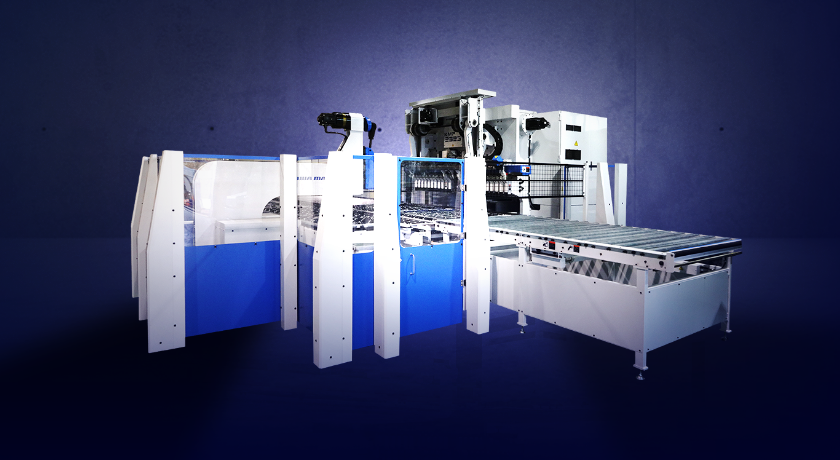

KMP LINE

Automated Production,

Enhanced Power

- The high-precision, high-efficiency KMP Line supports evolution toward fully automated manufacturing.

- We propose the optimal line configuration based on your product specifications and production style.

- Flexible customization and excellent scalability make it easy to meet a wide range of needs.

- A next-generation manufacturing solution that comprehensively supports labor-saving, productivity improvement, and quality stability.